Our Brands

Industrial Hydraulics stock a range of quality brands with a hose to suit almost any application.

From high pressure applications to temperature extremes and aggressive fluids, we can source a hose to do the job.

Aeroquip’s AQP range of hoses are scientifically superior to any other hose on the market today. Since the launch of AQP hose in the early 1970’s it has become widely regarded as the best performing range of high temperature hose 150˚C (Except water 82˚C and air 121˚C) available. AQP hose service life can outlast conventional hose by up to five times.

The advantages are clear, longer service life means less equipment maintenance, less downtime, increased productivity and better value for money.

Hydraulic Hose

Disclaimer: While we have taken utmost care to ensure the accuracy of all specifications

and data provided, we cannot guarantee absolute precision and recommend users

verify information independently if necessary.

1SN

1SN

EN853 1SN Meets SAE100R1AT EC110** GENUINE DANFOSS & 1SN* GENERIC BRAND THIS CHART IS INTENDED FOR REFERENCES PURPOSES

-

Construction

Synthetic rubber tube

Single wire braid reinforcement

Synthetic rubber cover

White ink transfer layline -

Application

Hydraulics system service with

petroleum and water-based fluids

General industrial service -

Approved Fittings

TTC series

Danfoss Field Attachable

Winner 2-piece (non-skive)

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| 1SN-04** | 6.4 | 0.25 | 13.4 | 0.53 | 225 | 3265 | 900 | 13050 | 100 | 3.94 | 0.21 | 0.14 |

| EC110-06* | 9.5 | 0.38 | 18.1 | 0.71 | 180 | 2600 | 720 | 10400 | 130 | 5.12 | 0.33 | 0.22 |

| EC110-08* | 12.7 | 0.50 | 21.4 | 0.84 | 160 | 2300 | 640 | 9200 | 180 | 7.09 | 0.41 | 0.28 |

| 1SN-12** | 19.0 | 0.75 | 27.7 | 1.09 | 105 | 1525 | 420 | 6090 | 240 | 9.45 | 0.58 | 0.39 |

| 1SN-16** | 25.4 | 1.0 | 35.6 | 1.40 | 88 | 1275 | 350 | 5070 | 300 | 11.81 | 0.88 | 0.59 |

100R17

GH681

EN857 TYPE 1SC EXCEEDS SAE 100R17

-

Construction

Synthetic rubber tube

Single wire braid reinforcement

Synthetic rubber cover

White ink transfer layline -

Application

Hydraulics system service with

petroleum and water-glycol base

fluids

General industrial service -

Approved Fittings

TTC series

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| GH681-04 | 6.4 | 0.25 | 13.4 | 0.53 | 255 | 3700 | 1020 | 14800 | 50 | 1.97 | 0.14 | 0.09 |

| GH681-06 | 9.7 | 0.38 | 16.7 | 0.66 | 235 | 3400 | 940 | 13600 | 63 | 2.48 | 0.22 | 0.15 |

| GH681-08 | 12.7 | 0.50 | 20.3 | 0.80 | 200 | 3200 | 883 | 12800 | 90 | 3.54 | 0.45 | 0.30 |

| GH681-10 | 16.0 | 0.63 | 23.1 | 0.91 | 140 | 2025 | 559 | 8100 | 100 | 3.94 | 0.50 | 0.34 |

| GH681-12 | 19.0 | 0.75 | 26.6 | 1.05 | 138 | 2000 | 552 | 8000 | 120 | 4.72 | 0.67 | 0.45 |

| GH681-16 | 25.4 | 1.00 | 34.8 | 1.37 | 103 | 1500 | 414 | 6000 | 150 | 5.91 | 1.01 | 0.68 |

| GH681-20 | 31.7 | 1.25 | 42.4 | 1.67 | 69 | 1000 | 276 | 4000 | 210 | 8.27 | 1.31 | 0.88 |

| GH681-24 | 38.1 | 1.50 | 49.0 | 1.93 | 52 | 750 | 207 | 3000 | 250 | 9.84 | 1.57 | 1.05 |

| GH681-32 | 50.8 | 2.00 | 63.0 | 2.48 | 41 | 600 | 166 | 2400 | 315 | 12.40 | 1.95 | 1.31 |

2SN

Winner EC210

-

Construction

Synthetic rubber tube

Double wire braid reinforcement

Synthetic rubber cover

Green ink transfer layline

-

Application

Hydraulic system service with petroleum and water-based fluids for general industrial service

-

Approved Fittings

TTC series

Danfoss Field Attachable

Winner 2-piece (non-skive)

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| EC210-04 | 6.4 | 0.25 | 15.7 | 0.62 | 400 | 5800 | 1600 | 23200 | 100.0 | 3.94 | 0.38 | 0.26 |

| EC210-06 | 9.5 | 0.38 | 19.7 | 0.78 | 330 | 4800 | 1320 | 19200 | 130.0 | 5.12 | 0.54 | 0.36 |

| EC210-08 | 12.7 | 0.50 | 23.0 | 0.91 | 275 | 4000 | 1100 | 16000 | 180.0 | 7.09 | 0.64 | 0.43 |

| EC210-12 | 19.0 | 0.75 | 30.1 | 1.19 | 215 | 3125 | 860 | 12500 | 240.0 | 9.45 | 0.93 | 0.62 |

| EC210-16 | 25.4 | 1.00 | 38.9 | 1.53 | 165 | 2400 | 660 | 9600 | 300.0 | 11.81 | 1.29 | 0.87 |

GH195

EN853 2SN

-

Construction

AQP elastomer tube

Double wire braid reinforcement

Blue AQP elastomer cover -

Application

Hydraulic system service with petroleum, fire resistant and water-based fluids, fuel & lubricating systems.

-

Approved Fittings

TTC series

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| GH195-04 | 6.4 | 0.25 | 15.2 | 0.60 | 400 | 5800 | 1600 | 23200 | 101.6 | 4.0 | 0.40 | 0.27 |

| GH195-06 | 9.7 | 0.38 | 19.0 | 0.75 | 350 | 5000 | 1400 | 20000 | 127.0 | 5.0 | 0.58 | 0.39 |

| GH195-08 | 12.7 | 0.50 | 22.1 | 0.87 | 297 | 4250 | 1190 | 17000 | 177.8 | 7.0 | 0.69 | 0.46 |

| GH195-10 | 16.0 | 0.63 | 25.1 | 0.99 | 227 | 3250 | 897 | 13000 | 203.2 | 8.0 | 0.81 | 0.54 |

| GH195-12 | 19.0 | 0.75 | 29.5 | 1.16 | 210 | 3000 | 840 | 12000 | 241.3 | 9.5 | 1.00 | 0.67 |

| GH195-16 | 25.4 | 1.00 | 37.8 | 1.49 | 175 | 2500 | 700 | 10000 | 304.8 | 12.0 | 1.45 | 0.97 |

| GH195-20 | 31.7 | 1.25 | 48.7 | 1.92 | 157 | 2250 | 630 | 9000 | 419.1 | 16.5 | 2.39 | 1.61 |

| GH195-24 | 38.1 | 1.50 | 54.6 | 2.15 | 122 | 1750 | 490 | 7000 | 508.0 | 20.0 | 2.59 | 1.74 |

100R16

GH781

-

Construction

Synthetic rubber tube

Double wire braid reinforcement

Synthetic rubber cover

Green layline -

Application

Hydraulics system service with petroleum and water-glycol based fluids, for general industrial service

-

Approved Fittings

TTC series

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| GH781-04 | 6.4 | 0.25 | 13.5 | 0.53 | 448 | 6500 | 1792 | 26000 | 50.8 | 2.00 | 0.33 | 0.22 |

| GH781-06 | 9.7 | 0.38 | 17.5 | 0.69 | 400 | 5800 | 1600 | 23200 | 63.5 | 2.50 | 0.43 | 0.29 |

| GH781-08 | 12.7 | 0.50 | 20.6 | 0.81 | 345 | 5000 | 1380 | 20000 | 88.9 | 3.50 | 0.58 | 0.39 |

| GH781-10 | 16.0 | 0.63 | 23.6 | 0.93 | 276 | 4000 | 1104 | 16000 | 101.6 | 4.00 | 0.66 | 0.44 |

| GH781-12 | 19.0 | 0.75 | 27.9 | 1.10 | 241 | 3500 | 964 | 14000 | 120.7 | 4.75 | 0.79 | 0.53 |

| GH781-16 | 25.4 | 1.00 | 36.1 | 1.42 | 207 | 3000 | 828 | 12000 | 152.4 | 6.00 | 1.07 | 0.72 |

| GH781-20 | 31.8 | 1.25 | 41.9 | 1.65 | 172 | 2500 | 688 | 10000 | 209.6 | 8.25 | 1.63 | 1.10 |

| GH781-24 | 38.1 | 1.50 | 51.6 | 2.03 | 138 | 2000 | 552 | 8000 | 254.0 | 10.00 | 2.09 | 1.40 |

| GH781-32 | 50.8 | 2.00 | 64.3 | 2.53 | 110 | 1600 | 440 | 6400 | 317.5 | 12.50 | 2.83 | 1.90 |

EC215

EN857 2SC

-

Construction

INNER TUBE: Synthetic Rubber

REINFORCEMENT: Double wire braid

COVER: Synthetic Rubber

Green Layline -

Application

Hydraulics system service with

Petroleum and water-based

fluids, for general industrial service -

Approved Fittings

TTC Series

Winner 2-piece

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| EC215-04 | 6.4 | 0.25 | 13.5 | 0.53 | 400 | 5800 | 1600 | 23200 | 50 | 1.97 | 0.28 | 0.19 |

| EC215-06 | 9.5 | 0.38 | 17.5 | 0.69 | 345 | 5000 | 1380 | 20000 | 65 | 2.56 | 0.41 | 0.28 |

| EC215-08 | 12.7 | 0.50 | 20.8 | 0.82 | 275 | 4000 | 1100 | 16000 | 90 | 3.54 | 0.57 | 0.38 |

| EC215-10 | 15.9 | 0.62 | 24.0 | 0.94 | 250 | 3650 | 1000 | 14600 | 100 | 3.94 | 0.68 | 0.46 |

| EC215-12 | 19.0 | 0.75 | 27.9 | 1.10 | 215 | 3125 | 860 | 12500 | 120 | 4.72 | 0.81 | 0.54 |

| EC215-16 | 25.4 | 1.00 | 35.7 | 1.40 | 165 | 2400 | 660 | 9600 | 160 | 6.30 | 1.17 | 0.79 |

SELWASH 2SC

ISO 1307 RECOMMENDED FOR PROFESSIONAL WATER JET CLEANERS

-

Construction

2 high tensile steel wire braid

Oil, abrasion & weather resistant pin pricked special synthetic rubber -

Application

For high-pressure cleaning applications with hot water

-

Approved Fittings

Winner 2 piece

TTC Crimp

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| PW2SC-04 | 6.4 | 1/4″ | 13.4 | 0.53 | 400 | 5800 | 1600 | 23200 | 75.0 | 2.95 | 0.285 | 0.19 |

| PW2SC-06 | 9.5 | 3/8″ | 17.0 | 0.67 | 400 | 5800 | 1600 | 23200 | 90.0 | 3.54 | 0.420 | 0.28 |

100R12

GH493

EN856 4SP / SAE100R12

-

Construction

Synthetic rubber tube

4 spiral wire reinforcement

Synthetic rubber cover

Yellow layline -

Application

Hydraulics system service with petroleum and water-glycol-based fluids, for general industrial service

-

Approved Fittings

4S Crimp Fittings

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| GH493-06 | 9.5 | 0.38 | 20.0 | 0.79 | 448 | 6500 | 1792 | 26000 | 62 | 2.50 | 0.70 | 0.47 |

| GH493-08 | 12.7 | 0.50 | 23.4 | 0.92 | 415 | 6000 | 1660 | 24000 | 90 | 3.50 | 0.88 | 0.59 |

| GH493-10 | 16.0 | 0.63 | 28.2 | 1.11 | 415 | 6000 | 1660 | 24000 | 100 | 4.00 | 1.03 | 0.69 |

| GH493-12 | 19.0 | 0.75 | 30.5 | 1.20 | 380 | 5500 | 1520 | 22000 | 120 | 4.75 | 1.37 | 0.92 |

| GH493-16 | 25.4 | 1.00 | 37.6 | 1.48 | 350 | 5100 | 1400 | 20400 | 150 | 6.00 | 1.82 | 1.22 |

| GH493-20 | 31.8 | 1.25 | 46.5 | 1.83 | 310 | 4500 | 1240 | 18000 | 210 | 8.25 | 2.45 | 1.65 |

| GH493-24 | 38.1 | 1.50 | 53.8 | 2.12 | 275 | 4000 | 1100 | 16000 | 250 | 10.00 | 3.13 | 2.10 |

| GH493-32 | 50.8 | 2.00 | 67.1 | 2.64 | 275 | 4000 | 1100 | 16000 | 320 | 12.50 | 4.19 | 2.82 |

EC415

SAE 100R12

-

Construction

INNER TUBE: Synthetic rubber

REINFORCEMENT: 4 wire spiral

COVER: Synthetic rubber -

Application

Hydraulic systems service with

petroleum and water based fluids, for general use -

Approved Fittings

TTC series – 4S

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| EC415-12 | 19.0 | 0.75 | 30.7 | 1.21 | 280 | 4050 | 1120 | 16200 | 240 | 9.45 | 1.16 | 0.78 |

| EC415-16 | 25.4 | 1.00 | 38.0 | 1.50 | 280 | 4050 | 1120 | 16200 | 300 | 11.81 | 1.76 | 1.18 |

| EC415-20 | 31.8 | 1.25 | 47.0 | 1.85 | 210 | 3050 | 840 | 12200 | 420 | 16.54 | 2.46 | 1.65 |

| EC415-24 | 38.1 | 1.50 | 53.5 | 2.11 | 175 | 2550 | 700 | 10200 | 500 | 19.68 | 2.87 | 1.92 |

| EC415-32 | 50.8 | 2.00 | 66.7 | 2.63 | 175 | 2550 | 700 | 10200 | 630 | 24.80 | 4.03 | 2.70 |

100R5

FC300

AQP

-

Construction

AQP elastomer tube

Polyester inner braid

Single wire braid reinforcement

Blue polyester braid cover -

Application

Hydraulics handling petroleum base fluids and air, 91 octane

fuel, diesel and lubricating oils, fire-resistant hydraulic fluids and other industrial fluids -

Approved Fittings

SAE 100R5

R5 Crimp

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| FC300-04 | 4.8 | 0.19 | 13.2 | 0.52 | 210 | 3000 | 840 | 12000 | 76.2 | 3.00 | 0.19 | 0.13 |

| FC300-05 | 6.4 | 0.25 | 14.7 | 0.58 | 210 | 3000 | 840 | 12000 | 85.9 | 3.38 | 0.24 | 0.16 |

| FC300-06 | 7.9 | 0.31 | 17.0 | 0.67 | 157 | 2250 | 630 | 9000 | 101.6 | 4.00 | 0.34 | 0.23 |

| FC300-08 | 10.4 | 0.41 | 19.3 | 0.76 | 140 | 2000 | 560 | 8000 | 117.3 | 4.62 | 0.39 | 0.26 |

| FC300-10 | 12.7 | 0.50 | 23.6 | 0.93 | 122 | 1750 | 490 | 7000 | 139.7 | 5.50 | 0.55 | 0.37 |

| FC300-12 | 16.0 | 0.63 | 27.4 | 1.08 | 105 | 1500 | 420 | 6000 | 165.1 | 6.50 | 0.69 | 0.46 |

| FC300-16 | 22.4 | 0.88 | 32.3 | 1.27 | 56 | 800 | 224 | 3200 | 187.5 | 7.38 | 0.72 | 0.48 |

| FC300-20 | 28.4 | 1.12 | 38.1 | 1.50 | 43 | 625 | 175 | 2500 | 228.6 | 9.00 | 0.78 | 0.52 |

| FC300-24 | 35.0 | 1.38 | 44.5 | 1.75 | 35 | 500 | 140 | 2000 | 266.7 | 10.50 | 1.00 | 0.67 |

| FC300-32 | 46.0 | 1.81 | 56.4 | 2.22 | 21 | 300 | 84 | 1200 | 336.6 | 13.25 | 1.40 | 0.94 |

| FC300-40 | 60.5 | 2.38 | 73.2 | 2.88 | 21 | 300 | 84 | 1200 | 609.6 | 24.00 | 2.24 | 1.50 |

FC350

ENGINE & AIRBREAK

-

Construction

AQP elastomer tube

Polyester inner braid

Single wire braid reinforcement

Black polyester braid cover -

Application

Hydraulics, fuel &

lubricating oils, air & water -

Approved Fittings

SAE100R5 fittings

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| FC350-04 | 4.8 | 0.19 | 13.2 | 0.52 | 140 | 2000 | 560 | 8000 | 19.1 | 0.75 | 0.19 | 0.13 |

| FC350-05 | 6.4 | 0.25 | 14.7 | 0.58 | 105 | 1500 | 420 | 6000 | 25.4 | 1.00 | 0.24 | 0.16 |

| FC350-06 | 7.9 | 0.31 | 17.3 | 0.68 | 105 | 1500 | 420 | 6000 | 31.8 | 1.25 | 0.28 | 0.19 |

| FC350-08 | 10.4 | 0.41 | 19.6 | 0.77 | 87 | 1250 | 350 | 5000 | 44.5 | 1.75 | 0.33 | 0.22 |

| FC350-10 | 12.7 | 0.50 | 23.9 | 0.94 | 87 | 1250 | 350 | 5000 | 57.2 | 2.25 | 0.49 | 0.33 |

| FC350-12 | 16.0 | 0.63 | 27.4 | 1.08 | 52 | 750 | 210 | 3000 | 69.9 | 2.75 | 0.58 | 0.39 |

| FC350-16 | 22.4 | 0.88 | 31.2 | 1.23 | 28 | 400 | 112 | 1600 | 88.9 | 3.50 | 0.74 | 0.50 |

| FC350-20 | 28.4 | 1.12 | 38.1 | 1.50 | 21 | 300 | 84 | 1200 | 114.3 | 4.50 | 0.83 | 0.56 |

| FC350-24 | 35.1 | 1.38 | 44.45 | 1.75 | 17 | 250 | 70 | 1000 | 139.7 | 5.50 | 1.02 | 0.68 |

FC234

FIRE RESISTANT

-

Construction

AQP elastomer tube

Brass plated steel wire braid reinforcement

Braided refractory insulation and blue AQP elastomer cover -

Application

Diesel fuel, gasoline, hot lube oil and water

-

Approved Fittings

Danfoss Field Attachable

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| FC234-05 | 6.4 | 0.25 | 14.7 | 0.58 | 105 | 1500 | 420 | 6000 | 25.4 | 1.00 | 0.33 | 0.22 |

| FC234-06 | 7.9 | 0.31 | 17.3 | 0.68 | 105 | 1500 | 420 | 6000 | 31.8 | 1.25 | 0.37 | 0.25 |

| FC234-08 | 10.4 | 0.41 | 19.3 | 0.76 | 87 | 1250 | 350 | 5000 | 44.5 | 1.75 | 0.45 | 0.30 |

| FC234-10 | 12.7 | 0.50 | 23.9 | 0.94 | 87 | 1250 | 350 | 5000 | 57.2 | 2.25 | 0.67 | 0.45 |

| FC234-12 | 16.0 | 0.63 | 27.4 | 1.08 | 52 | 750 | 210 | 3000 | 69.9 | 2.75 | 0.72 | 0.48 |

| FC234-16 | 22.4 | 0.88 | 31.5 | 1.24 | 52 | 400 | 112 | 1600 | 88.9 | 3.50 | 0.76 | 0.51 |

TEXTILE PUSH ON

FC332

HIGH TEMP PUSH ON

-

Construction

AQP elastomer tube

Textile braid reinforcement

AQP elastomer cover -

Application

91 Octane fuel, Diesel and

Lubricating oils, air and water.

Not recommended for impulsing

application -

Approved Fittings

Socketless fittings

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| FC332-04 | 6.4 | 0.25 | 12.4 | 0.49 | 20 | 300 | 82 | 1200 | 63.5 | 2.5 | 0.12 | 0.08 |

| FC332-06 | 9.7 | 0.38 | 16.0 | 0.63 | 20 | 300 | 82 | 1200 | 76.2 | 3.0 | 0.18 | 0.12 |

| FC332-08 | 12.7 | 0.50 | 19.1 | 0.75 | 20 | 300 | 82 | 1200 | 127.0 | 5.0 | 0.22 | 0.15 |

| FC332-10 | 16.0 | 0.63 | 23.1 | 0.91 | 20 | 300 | 82 | 1200 | 152.4 | 6.0 | 0.30 | 0.20 |

| FC332-12 | 19.1 | 0.75 | 26.4 | 1.04 | 20 | 300 | 82 | 1200 | 177.8 | 7.0 | 0.42 | 0.28 |

100R4

WINNER WH004

HYDRAULIC SUCTION & RETURN HOSE

-

Construction

Tube: Oil resistant NBR

Reinforcement: Textile with helical & anti-static wire

Cover: Abrasion resistant synthetic rubber -

Application

Suitable for use in suction applications

for hydraulics, crude fuel, lubricating oils,

gasoline, air, water and chemical transfer. -

Approved Fittings

TTC Series

Winner 2-piece (non-skive)

Suction tails

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| WH004-12 | 19.0 | 0.75 | 30.0 | 1.18 | 21 | 305 | 84 | 1220 | 40.0 | 1.57 | 0.54 | 0.36 |

| WH004-16 | 25.4 | 1.00 | 36.2 | 1.43 | 17 | 245 | 68 | 980 | 45.0 | 1.77 | 0.68 | 0.46 |

| WH004-20 | 31.8 | 1.25 | 43.0 | 1.69 | 14 | 205 | 56 | 820 | 60.0 | 2.36 | 0.85 | 0.57 |

| WH004-24 | 38.1 | 1.50 | 50.2 | 1.98 | 10 | 150 | 42 | 600 | 65.0 | 2.56 | 1.20 | 0.81 |

| WH004-32 | 50.8 | 2.00 | 63.2 | 2.49 | 7 | 100 | 28 | 400 | 100.0 | 3.94 | 1.53 | 1.03 |

| WH004-40 | 53.5 | 2.50 | 76.7 | 3.02 | 4 | 60 | 16 | 240 | 140.0 | 5.51 | 2.05 | 1.38 |

| WH004-48 | 76.2 | 3.00 | 89.4 | 3.52 | 4 | 60 | 16 | 240 | 180.0 | 7.09 | 2.62 | 1.76 |

100R14

2807 TEFLON

PTFE / SAE 100R14A

-

Construction

Extruded Teflon tube with stainless

steel single wire braid reinforcement -

Application

Hot air, compressor discharge and most chemical applications.

Not recommended for steam-cold water cycling -

Approved Fittings

Danfoss Field Attachable

Crimp fittings

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| 2807-03 | 3.6 | 0.14 | 6.4 | 0.25 | 210 | 3000 | 840 | 12000 | 38.1 | 1.5 | 0.06 | 0.04 |

| 2807-04 | 4.8 | 0.19 | 7.6 | 0.30 | 210 | 3000 | 840 | 12000 | 50.8 | 2.0 | 0.09 | 0.06 |

| 2807-05 | 6.6 | 0.26 | 9.4 | 0.37 | 210 | 3000 | 840 | 12000 | 76.2 | 3.0 | 0.12 | 0.08 |

| 2807-06 | 8.1 | 0.32 | 10.9 | 0.43 | 175 | 2500 | 700 | 10000 | 101.6 | 4.0 | 0.15 | 0.10 |

| 2807-08 | 10.7 | 0.42 | 13.7 | 0.54 | 140 | 2000 | 560 | 8000 | 133.4 | 5.25 | 0.18 | 0.12 |

| 2807-10 | 13.0 | 0.51 | 16.0 | 0.63 | 105 | 1500 | 420 | 6000 | 165.1 | 6.5 | 0.24 | 0.16 |

| 2807-12 | 16.3 | 0.64 | 19.3 | 0.76 | 84 | 1200 | 335 | 4800 | 196.9 | 7.75 | 0.27 | 0.18 |

| 2807-16 | 22.4 | 0.88 | 26.2 | 1.03 | 70 | 1000 | 280 | 4000 | 228.6 | 9.0 | 0.39 | 0.26 |

| 2807-20 | 28.4 | 1.12 | 32.8 | 1.29 | 43 | 625 | 175 | 2500 | 406.4 | 16.0 | 0.51 | 0.34 |

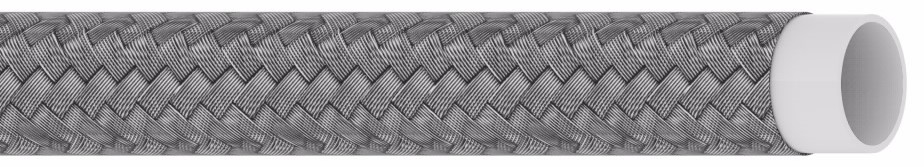

PTFE

Flexible PTFE Hose

-

Construction

Internal Core: smooth PTFE

Reinforcement: AISI 304 Stainless

Steel braid -

Application

PTFE hoses are mainly used for conduction of water, oil, fuel and steam.

PTFE is extremely resistant to corrosion, it is chemically inert, insoluble, non-flammable, and allows a good isolation.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| PTFE-04 | 6.45 | 0.25 | 9.19 | 0.36 | 181 | 2625 | 724 | 10500 | 76 | 2.99 | – | – |

| PTFE-06 | 9.52 | 0.37 | 12.7 | 0.50 | 155 | 2248 | 621 | 9006 | 127 | 5.00 | – | – |

| PTFE-08 | 12.8 | 0.50 | 16.08 | 0.63 | 103 | 1494 | 414 | 6004 | 165 | 6.50 | – | – |

| PTFE-12 | 19.0 | 0.75 | 22.22 | 0.87 | 76 | 1102 | 303 | 4394 | 229 | 9.02 | – | – |

| PTFE-16 | 25.4 | 1.00 | 28.83 | 1.14 | 62 | 899 | 248 | 3596 | 305 | 12.00 | – | – |

TWCPTFE

Flexible PTFE Hose Tape Wrapped Convoluted

-

Construction

Low profile helically convoluted PTFE (polytetrafluorethylene) liner, glassfibre reinforced, with a AISI 304 high tensile, stainless steel braid.

-

Application

Used globally in applications that require a tighter bend radius whilst still requiring the unparalleled qualities of a PTFE hose.

Not suitable for steam – cold water cycling applications.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| TWCPTFE-12 | 19.85 | 0.75 | 26.87 | 1.07 | 76 | 110 | 4400 | 308 | 64 | 2.5 | ||

| TWCPTFE-16 | 25.88 | 1 | 32.90 | 1.34 | 60 | 875 | 3500 | 241 | 76 | 3.0 | ||

| TWCPTFE-20 | 32.30 | 1.25 | 39.78 | 1.57 | 60 | 875 | 3500 | 241 | 88 | 3.5 | ||

| TWCPTFE-24 | 38.85 | 1.5 | 45.70 | 1.81 | 52 | 750 | 3000 | 207 | 114 | 4.5 | ||

| TWCPTFE-32 | 51.18 | 2 | 59.20 | 2.32 | 34 | 500 | 2000 | 138 | 133 | 5.25 | ||

100R7 Thermoplastic

ZR7

R7-LT Thermoplastic hose Waterproof cover

-

Construction

Inner core in thermoplastic polyester, reinforcement in polyester textile and exterior covering in anti-abrasion polyurethane stabilised against UV rays and resistant to hydrolysis and micro-organisms, suitable for outdoor applications in environments having high humidity and saline levels, pinpricked for conduction of air and compatible gases.

-

Application

For operating machines & lift trucks that work at low temperatures. High Pressure Hydraulic applications in Marine environments.

The waterproof feature of the cover means that the hose is especially suitable for wet and saline environments where there are extreme temperature changes.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZR7-03** | 4.8 | 3/16″ | 10.0 | 0.39 | 210 | 3045 | 840 | 12180 | 30 | 1.18 | 0.073 | 0.049 |

| ZR7-04** | 6.4 | 1/4″ | 11.8 | 0.46 | 200 | 2900 | 800 | 11600 | 35 | 1.38 | 0.090 | 0.060 |

| ZR7-06** | 9.7 | 3/8″ | 16.0 | 0.63 | 175 | 2538 | 700 | 10152 | 55 | 2.17 | 0.155 | 0.104 |

ZR7N

Non-conductive R7 Thermoplastic hose Waterproof cover Safety ratio 1:4 is required in the case in which the breaking of the tubing may cause the rig or the load lifting device or both to move Safety ration 1:3 is acceptable in the case in which the breaking of tubing does not cause the aerial lifting devices to move

-

Construction

Inner core in thermoplastic polyester, reinforcement in polyester textile and exterior covering in orange anti-abrasion polyurethane not micro perforated, stabilised against UV rays and microorganisms-resistant.

The waterproof feature of the cover means that the hose is especially suitable for wet and saline environments where there are extreme temperature changes. -

Application

Created for medium pressure hydraulic use for applications requiring high electrical isolation.

These hoses meet SAEJ517 Standard

§20.4.1 for less than 50µA leakages under 250.000 V/m, suitable for air traveling platforms

Solution for lifting platforms and other systems requiring isolation

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZR7N-04 | 6.4 | 1/4″ | 11.8 | 0.46 | 200 | 2900 | 800 | 11600 | 35 | 1.38 | 0.090 | 0.060 |

| ZR7N-06 | 9.7 | 3/8″ | 16.0 | 0.63 | 175 | 2538 | 700 | 10152 | 55 | 2.17 | 0.155 | 0.104 |

| ZR7N-08 | 13.0 | 1/2″ | 20.3 | 0.80 | 140 | 2030 | 560 | 8120 | 75 | 2.95 | 0.219 | 0.147 |

100R8 Thermoplastic

R8

Thermoplastic hose – waterproof cover **Not MSHA rated **Oil proof cover **Not for Marine use

-

Construction

INNER CORE: Thermoplastic polyester, high toughness textile fiber.

EXTERIOR COVER: Anti-abrasion polyurethane stabilised to UV rays & resistant to hydrolosis & micro-organisms. Micro perforated for air & compatible gas. -

Application

For High Pressure hydraulic use in environments

having a high levels of humidity.

For outdoor Applications in Marine

Micro perforated for the conduction of air and compatible gases, resistant to stabilized hydrolysis for outdoor applications in environments having high humidity and saline levels, stabilised against UV rays and microorganisms-resistant.

The waterproof feature of the cover means that the hose is especially suitable for wet and saline environments where there are extreme temperature changes.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZR8-02 | 3.5 | 1/8″ | 7.1 | 0.28 | 420 | 6091 | 1680 | 24366 | 30.0 | 1.18 | 0.037 | 0.025 |

| ZR8-03** | 4.8 | 3/16 | 10.0 | 0.39 | 350 | 5076 | 1400 | 20305 | 35.0 | 1.38 | 0.072 | 0.048 |

| ZR8-04 | 6.4 | 1/4″ | 11.8 | 0.46 | 350 | 5076 | 1400 | 20305 | 50.0 | 1.97 | 0.097 | 0.065 |

| ZR8-06 | 9.7 | 3/8″ | 16.0 | 0.63 | 280 | 4061 | 1120 | 16244 | 70.0 | 2.76 | 0.149 | 0.100 |

| ZR8-08 | 13.0 | 1/2″ | 20.3 | 0.80 | 245 | 3553 | 980 | 14213 | 95.0 | 3.74 | 0.225 | 0.151 |

| ZR8-12 | 19.2 | 3/4″ | 26.5 | 1.04 | 165 | 2393 | 660 | 9572 | 150.0 | 5.91 | 0.352 | 0.237 |

Specialty

ZGR7PA – GREASE HOSE

Thermoplastic Grease Hose – Water-proof Cover

-

Construction

Inner core in polyamide, braided reinforcement of polyester fiber and outer covering of matte black polyurethane.

-

Application

Developed for high pressure transfer of lubricants and grease.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZGR7PA | 4.0 | 5/32″ | 8.6 | 0.34 | 280 | 4061 | 840 | 12183 | 20 | 0.79 | 0.046 | 0.031 |

ZJH – JACKING HOSE

Thermoplastic Jacking Hose Dynamic Pressure – Waterproof Cover

-

Construction

The inner core is made of polyamide, reinforcement of Aramid fiber and high tensile steel braid and the exterior covering is made of polyether anti-scratch polyurethane, resistant to hydrolysis and stabilised for outdoor applications, micro perforated on request for the conduction of air and compatible gases.

-

Application

Created for very high pressure conduction of Polyols, solvents, paints & hydraulic fluids for dynamic systems (rescue tools, hydraulic jack applications).

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZJH-04 | 6.4 | 1/4″ | 14.5 | 0.57 | 700 | 10152 | 2800 | 40608 | 40 | 1.57 | .242 | 0.162 |

| ZJH-04R | 6.4 | 1/4″ | 14.5 | 0.57 | 700 | 10152 | 2800 | 40608 | 40 | 1.57 | .242 | 0.162 |

ZR18T

Thermoplastic Forklift Hose – Twin Line

-

Construction

Inner core in thermoplastic polyester elastomer (TPE), bonded reinforcement in high tenacity polyester fiber, and outer covering in black glossy special polyester, pinpricked, UV light stabilised and resistant to extreme temperatures for outdoor applications.

-

Application

Created for the high pressure Hydraulics, especially for operating over pulley in heavy duty applications. Eg. Forklift, cranes and boom lifts, even

Working at low temperature.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZR18T-06 | 9.8 | 3/8″ | 16.6 | 0.65 | 210 | 3045 | 840 | 12180 | 45 | 1.77 | 0.322 | 0.216 |

SELWASH 2SC

ISO 1307 RECOMMENDED FOR PROFESSIONAL WATER JET CLEANERS

-

Construction

2 high tensile steel wire braid

Oil, abrasion & weather resistant pin pricked special synthetic rubber -

Application

For high-pressure cleaning applications with hot water

-

Approved Fittings

Winner 2 piece

TTC Crimp

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| PW2SC-04 | 6.4 | 1/4″ | 13.4 | 0.53 | 400 | 5800 | 1600 | 23200 | 75.0 | 2.95 | 0.285 | 0.19 |

| PW2SC-06 | 9.5 | 3/8″ | 17.0 | 0.67 | 400 | 5800 | 1600 | 23200 | 90.0 | 3.54 | 0.420 | 0.28 |

Jetter Hose

The water-proof feature of the cover means that the hose is especially suitable for wet & saline environments where there are extreme temperature changes.

-

Construction

Inner core in thermoplastic polymer, reinforcement in high tensile fiber braids

Outside cover in anti-abrasion polyurethane, stabilised to UV rays and resistant to hydrolysis for outdoor applications, in environments having high humidity level. -

Application

Developed for high pressure water jetting

applications for cleaning & purging of

industrial & domestic lateral sewage lines.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZJCL-04 | 6.4 | 1/4″ | 12.2 | 0.48 | 345 | 5003 | 862 | 12502 | 50 | 1.97 | 0.087 | 0.058 |

| ZJCL-06 | 9.7 | 3/8″ | 16.8 | 0.66 | 345 | 5003 | 862 | 12502 | 75 | 2.95 | 0.156 | 0.105 |

Jetter Hose Large Sizes

The water-proof feature of the cover means that the hose is especially suitable for wet & saline environments where there are extreme temperature changes.

-

Construction

Inner core in thermoplastic compound, reinforcement in double polyester fiber braid and outside covering in antiabrasion polyurethane, pin-pricked, stabilised to UV rays and resistant to hydrolysis for outdoor applications, in environments having high humidity and saline levels.

-

Application

The JC7 series hoses have been created for water applications in the high pressure cleaning field.

| Part no. | Hose I.D | Hose O.D | Max Working Pressure | Min Burst Pressure | Min Bend Radius | Weight | ||||||

| MM | IN | MM | IN | Bar | Psi | Bar | Psi | MM | IN | Kg/M | Lb/Ft | |

| ZJCL-08 | 13.0 | 1/2″ | 22.4 | 0.88 | 275 | 3988 | 687 | 9964 | 75 | 2.95 | 0.277 | 0.186 |

| ZJCL-12 | 19.2 | 3/4″ | 29.8 | 1.17 | 207 | 3002 | 517 | 7500 | 120 | 4.72 | 0.431 | 0.290 |

| ZJCL-16 | 32.0 | 1″ | 46.0 | 1.81 | 207 | 3002 | 517 | 7500 | 235 | 9.25 | 0.926 | 0.622 |

CONTACT US FOR YOUR DISCOUNT

For any enquiries, please call our friendly staff on 07 3205 3612 or email [email protected]

Hose Protection

FF90754 – GUARDIAN SLEEVE (BURST)

Guardian Sleeve: Designed to provide protection against hydraulic hose failure by containing pressure and fluids that may escape during a hose burst or pinhole leak.

| PART # | SIZE – INCHES (ID) |

|---|---|

| FF90754-68 | 0.68” |

| FF90754-79 | 0.79” |

| FF90754-91 | 0.91” |

| FF90754-98 | 0.98” |

| FF90754-106 | 1.06” |

| FF90754-122 | 1.22” |

| FF90754-142 | 1.42” |

| FF90754-157 | 1.57” |

| FF90754-173 | 1.73” |

| FF90754-185 | 1.85” |

| FF90754-209 | 2.09” |

| FF90754-219 | 2.19” |

| FF90754-238 | 2.38” |

| FF90754-288 | 2.88” |

| FF90754-366 | 3.66” |

FC425 – Abrasion Sleeve

Nylon sleeve protects hose from abrasion and allows bundling of hose lines.

| PART # | SIZE – INCHES (ID) |

|---|---|

| FC425-12 | 0.71” |

| FC425-16 | 1.00” |

| FC425-18 | 1.13” |

| FC425-20 | 1.25” |

| FC425-24 | 1.59” |

| FC425-28 | 1.75” |

| FC425-32 | 2.07” |

| FC425-38 | 2.38” |

| FC425-54 | 3.34” |

| FC425-59 | 3.66” |

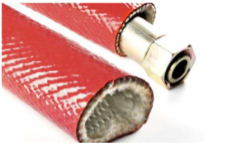

624 – FIRESLEEVE

Firesleeve: Protects hose from direct flame. Firesleeve is constructed of a uniform single layer of braided fibreglass tubing impregnated with flame resistant silicone rubber.

| PART # | SIZE – INCHES (ID) |

| 624-08 | 0.50” |

| 624-10 | 0.62” |

| 624-12 | 0.75” |

| 624-14 | 0.88” |

| 624-16 | 1.00” |

| 624-20 | 1.25” |

| 624-22 | 1.38” |

| 624-24 | 1.50” |

| 624-26 | 1.62” |

| 624-30 | 1.88” |

| 624-32 | 2.00” |

| 624-38 | 2.38” |

| 624-46 | 2.88” |

| 624-54 | 3.38” |

PHR – PIGS TAIL

Spiral Wrap: Recommended to protect hose from abrasion, this light weight plastic sleeve is unaffected by air, water, oil, gasoline, hydraulic and most other fluids. This coil can also be used for group bundling of hose lines.

| PART # | SIZE – MM (ID) |

| PHR09 | 9mm |

| PHR12 | 12mm |

| PHR16 | 16mm |

| PHR19 | 19mm |

| PHR20 | 20mm |

| PHR25 | 25mm |

| PHR32 | 32mm |

| PHR40 | 40mm |

| PHR50 | 50mm |

| PHR75 | 75mm |

| PHR90 | 90mm |